Stockouts at the point of care

When critical supplies run short, teams lose time and care is disrupted. Visibility and replenishment routines keep the right items available.

Controla suministros, equipos y movimientos en el punto de uso con responsabilidad auditable. Estandariza recepción, distribución y conteos entre salas y sedes para reducir quiebres, mermas y compras de urgencia.

Keep supplies and equipment accurate at the point of use: standardize distribution, transfers, and counts across rooms and sites with audit-ready accountability.

En salud, la precisión del inventario impacta costo y atención. Las operaciones de inventario ayudan a mantener suministros y equipos correctos en el punto de uso—con responsabilidad, trazabilidad y evidencia para auditorías y revisiones.

La mayoría empieza aquí. IO ayuda a reducir deriva, mejorar precisión y mantener un rastro confiable.

When critical supplies run short, teams lose time and care is disrupted. Visibility and replenishment routines keep the right items available.

Equipment moves between rooms and teams. Track custody and location history so accountability is clear.

Reviews require defensible evidence. Preserve movement and adjustment history so audits don’t become manual reconstruction exercises.

IO estandariza seguimiento, controles y evidencia—para operar con confianza entre sedes e interesados.

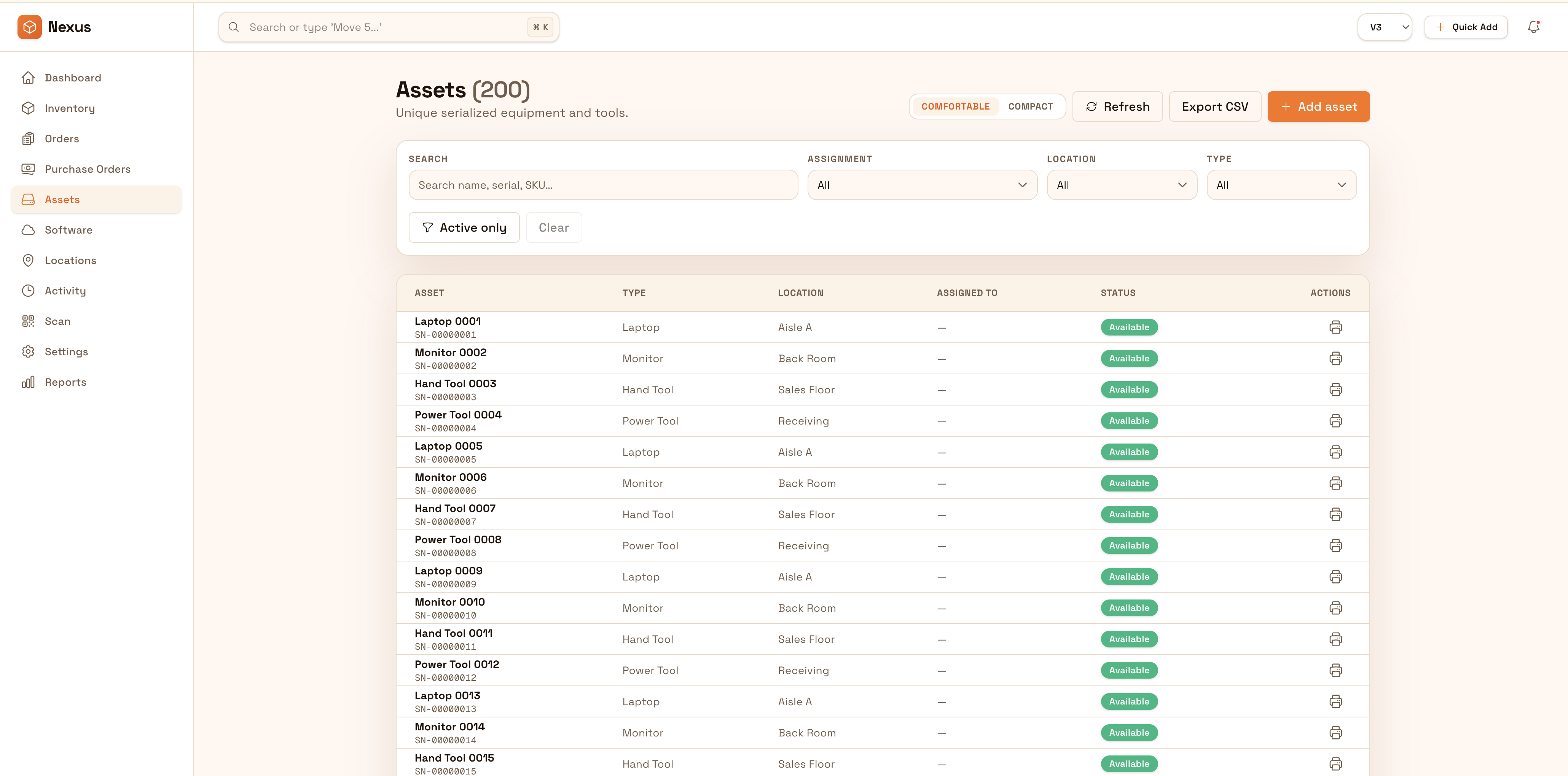

• Supplies by rooms, carts, cabinets, and sites • Distribution events and transfers between locations • Shared equipment custody and lifecycle notes • Exceptions (expired, damaged) with documentation • Exportable reporting for audits and reviews

Create room/cabinet location structure so counts and replenishment remain consistent.

Record movements between supply rooms and points of care to keep stock accurate.

Use cycle counts to keep accuracy high without disruptive full counts.

Export movement history and summaries for audits, inspections, and internal reviews.

Cuéntanos tus requisitos de cumplimiento y operación. Recomendaremos el despliegue correcto.

Use role-based access and approvals where needed, and preserve who/when/why for movements and adjustments so evidence is defensible.

Los mayores beneficios suelen ser precisión, velocidad y responsabilidad defendible.

Yes—use room/cabinet/cart location structure so distribution is traceable.

Yes—visibility and replenishment routines keep critical supplies available.

Yes—track custody and lifecycle notes so equipment stays accountable.

Yes—exports provide summaries and movement history for reviews.

Start with the main supply areas and the highest-impact point-of-use locations.