Equipment is shared across teams

When equipment is booked and shared, custody gaps create conflict. Track assignments and transfers so “who has it” is always clear.

Rastrea equipos de alto valor entre departamentos y sedes con visibilidad completa de ciclo de vida. Conecta asignación, inspecciones, mantenimiento y movimientos para probar dónde está y qué cambió con el tiempo.

Keep high-value equipment accountable and ready: track assignments, inspections, maintenance, and movement history so teams reduce downtime and prove where equipment has been.

El seguimiento de equipos protege activos de alto valor y mantiene equipos listos. Las operaciones de inventario conectan asignación, ubicación, inspecciones e historial de mantenimiento—para probar dónde está, en qué condición y qué cambió con el tiempo.

La mayoría empieza aquí. IO ayuda a reducir deriva, mejorar precisión y mantener un rastro confiable.

When equipment is booked and shared, custody gaps create conflict. Track assignments and transfers so “who has it” is always clear.

Inspection and maintenance notes often live in emails or tickets. Keep maintenance history attached to the equipment record.

Incidents and audits require evidence. Preserve changes with context so condition and responsibility are defensible.

IO conecta ubicaciones, historial de movimientos y controles—para que equipos avancen sin perder trazabilidad.

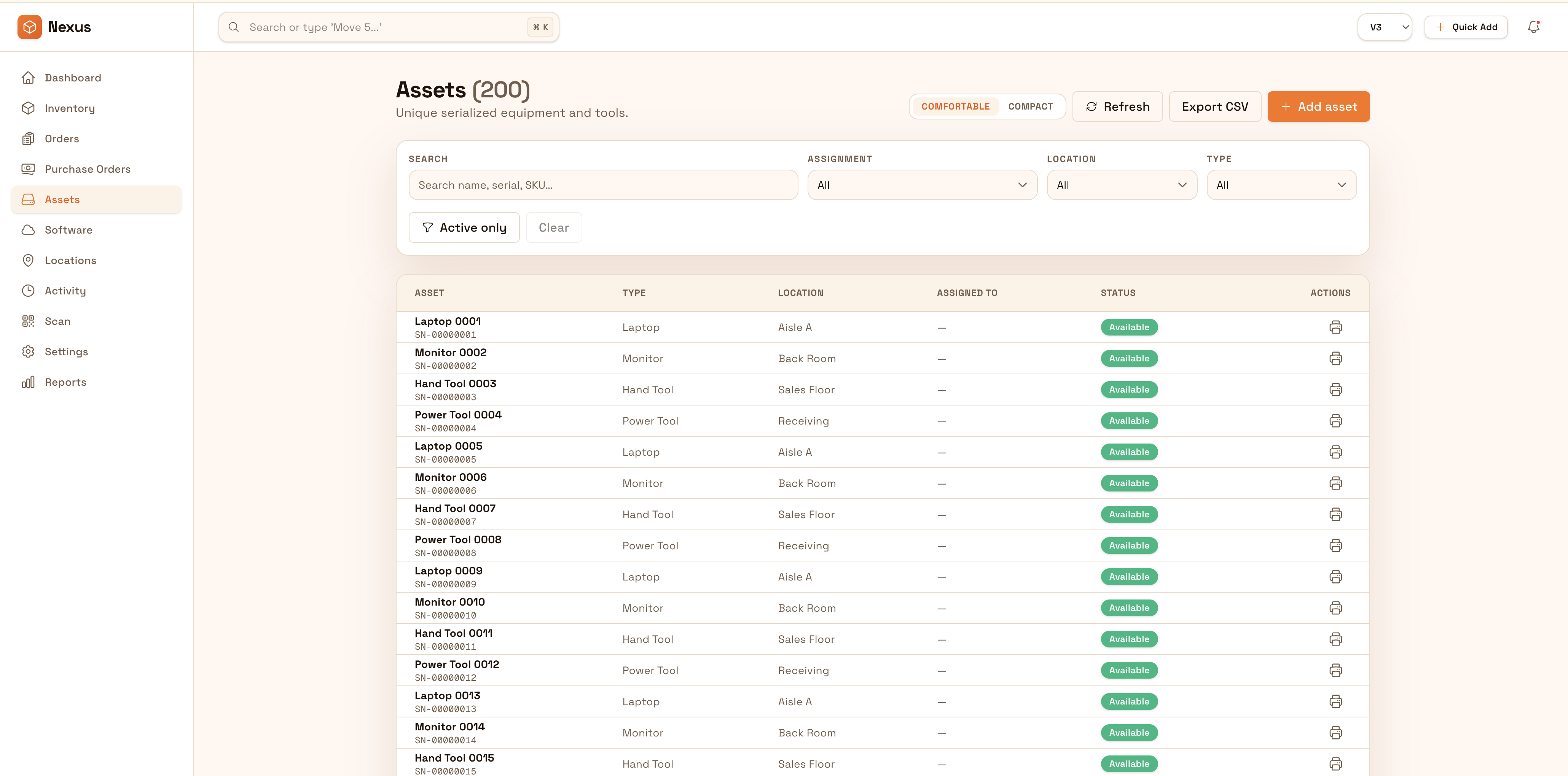

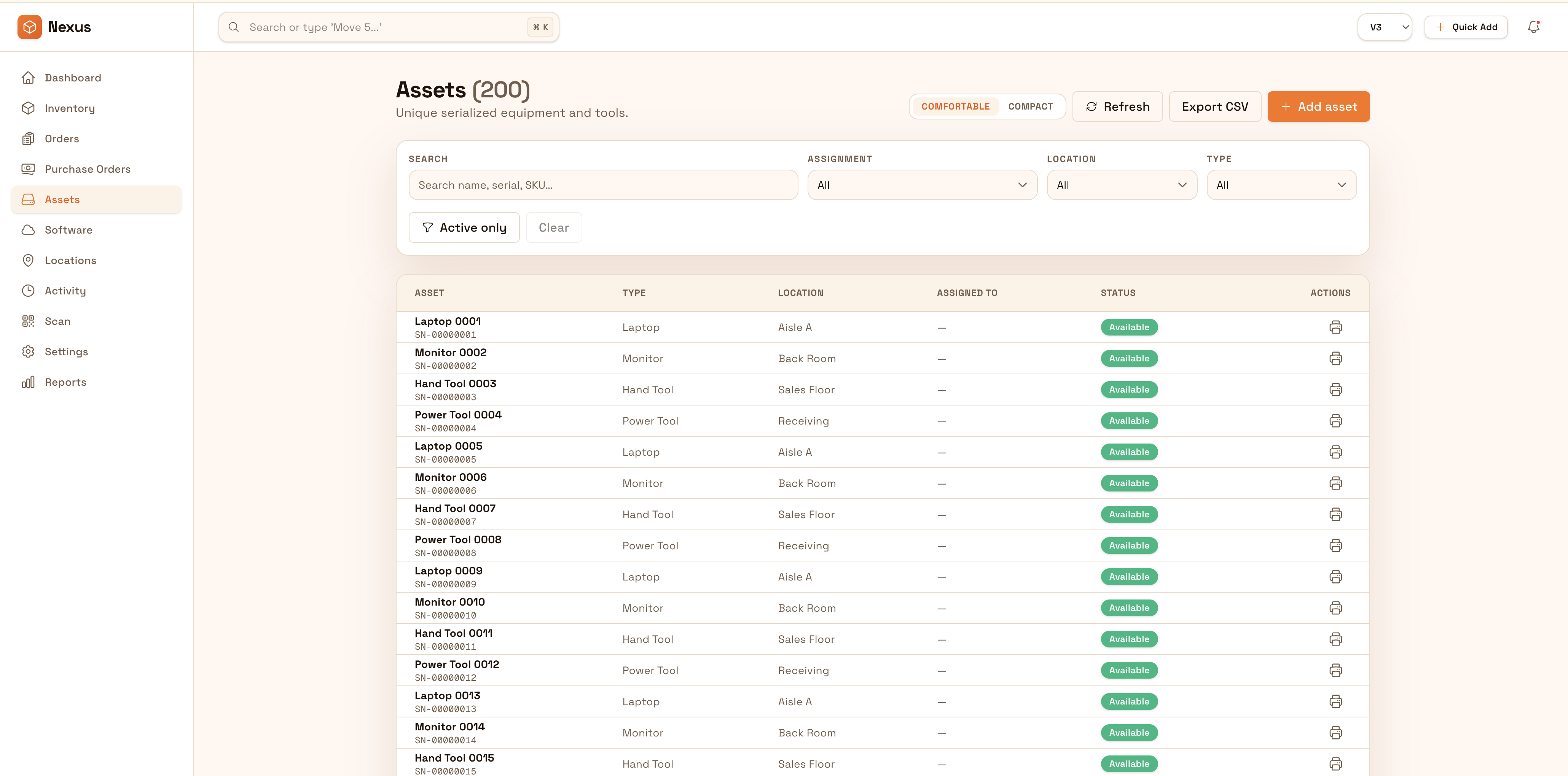

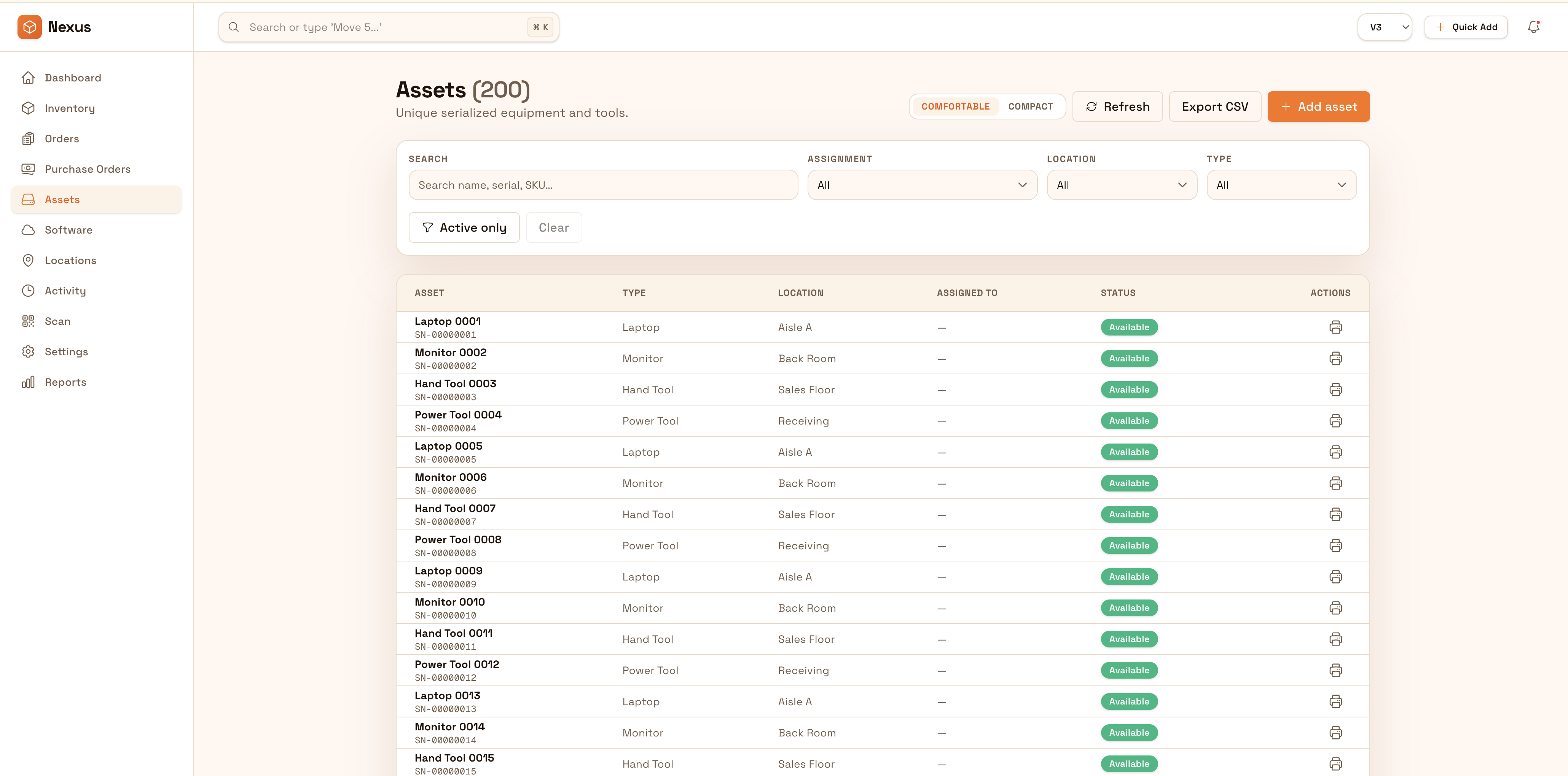

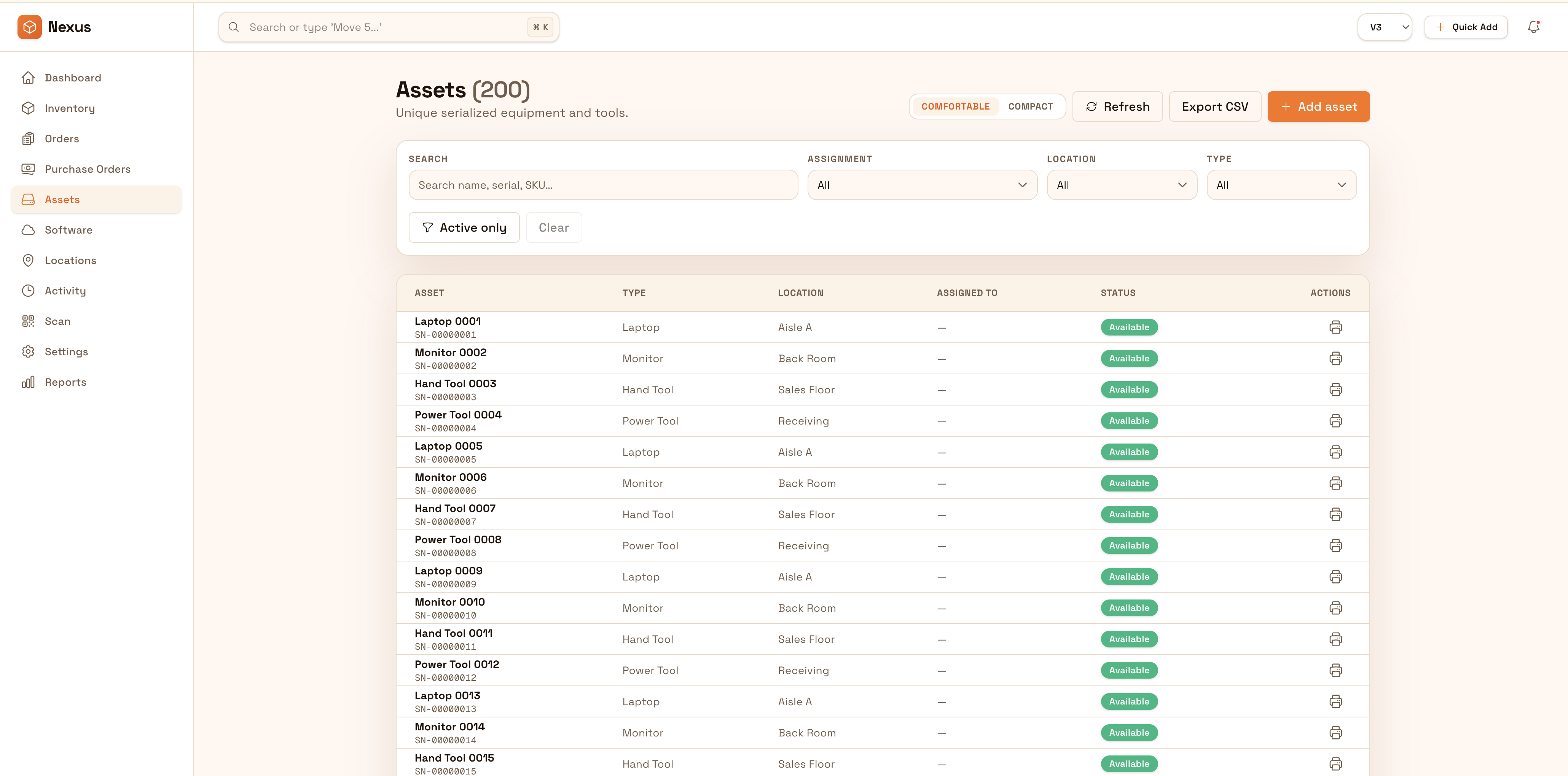

• Equipment identity and current location • Assignments, reservations, and custody trail • Inspection and maintenance notes • Status changes (in service, out for repair, retired) • Exports for audits and operational review

Create a single source of truth with identity details and home location.

Record assignments and transfers so custody stays visible as equipment moves.

Capture notes and status changes so readiness is always known.

Export assignment and history reports to answer questions without manual reconstruction.

Cuéntanos cómo operas este proceso hoy. Recomendaremos configuración y despliegue.

Control who can change status or retire equipment, and require notes for exceptions. The audit trail preserves the story of each asset over time.

Export equipment lists and history for audits and management reviews. Integrate with maintenance or ticketing workflows to keep updates consistent.

Yes—model sites and locations, then record transfers so custody stays clear.

Yes—capture maintenance notes and status changes in the equipment record.

Readiness comes from consistent status and maintenance updates tied to each asset.

Yes—exports make audits and incident reviews faster and more defensible.

Start with high-value equipment and a simple assignment workflow, then expand to maintenance and reporting.